How to Choose the Right Plastic Tray for Storage, Food, and Professional Use

Whether someone is comparing a large plastic tray for bulk handling or evaluating trays designed for food or dental use, the decision is rarely about appearance alone. It’s about function, efficiency, and long-term reliability.

Understanding Size and Load Requirements

One of the most common buying motivations is scale. A large plastic tray is typically chosen when users need to transport multiple items at once or manage heavier loads. Larger trays reduce repeated trips and improve workflow efficiency in kitchens, warehouses, and commercial settings.

However, size should be matched with structural support. Reinforced bases, edge stability, and balanced weight distribution matter more than simply increasing dimensions. A tray that flexes under pressure quickly becomes unreliable.

For food environments, large plastic trays for food must also maintain shape when exposed to temperature changes or repeated washing. Durability isn’t optional — it directly affects safety and hygiene.

Organization and Workflow Efficiency

A plastic tray organizer goes beyond holding items. It helps create structure. In office drawers, tool benches, or kitchen prep zones, segmented trays minimize clutter and speed up task completion.

The value of organization is often underestimated. When each component has a defined place, errors decrease and productivity rises. That’s why trays with modular sections or stackable designs are increasingly preferred in both household and professional environments.

Similarly, a plastic tray container combines storage and mobility. These trays act as temporary staging platforms — moving items between locations without requiring repacking. This is especially useful in logistics, retail restocking, and workshop operations.

Food Safety and Material Considerations

When selecting a plastic tray for food, material quality becomes critical. Food-contact trays should resist staining, odor retention, and chemical breakdown. Smooth surfaces simplify cleaning and reduce contamination risk.

Buyers often focus on certifications and manufacturing consistency. Reliable trays are built to withstand repeated sanitation cycles without cracking or warping. In high-use kitchens, this durability directly translates into lower replacement frequency.

Temperature tolerance is another practical factor. Trays exposed to refrigeration or warm environments must maintain structural integrity, ensuring safe food handling across preparation stages.

Specialized Industry Applications

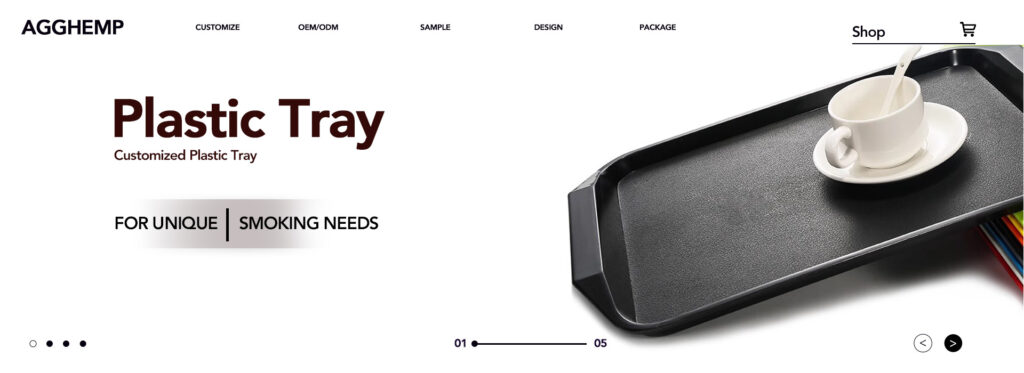

Certain sectors demand trays designed for precise workflows. A plastic tray dental setup, for example, must accommodate instrument organization while supporting strict hygiene protocols. Easy sterilization, chemical resistance, and ergonomic handling are essential features.

These industry-focused trays demonstrate how design evolves around workflow. Rather than being generic containers, they function as integrated tools that support efficiency and compliance.

Comparing Purchase Channels vs. Purpose-Built Solutions

Many buyers begin their search through familiar retail comparisons such as plastic tray walmart or plastic tray amazon listings. These platforms offer convenience and variety, but the trays available are often standardized.

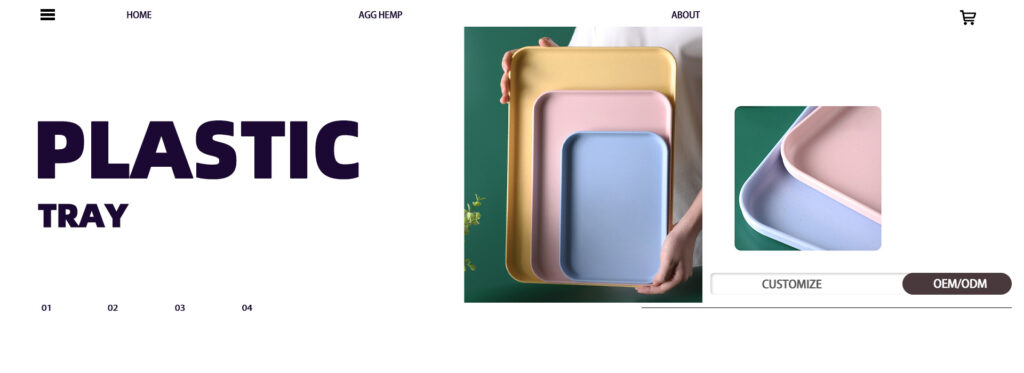

For users with specific needs — unusual dimensions, professional requirements, or branding preferences — purpose-built solutions provide greater flexibility. Custom sizing, reinforced structures, or specialized surface finishes can significantly improve usability in demanding environments.

The key takeaway is that trays should be selected based on operational needs rather than convenience alone. A tray that matches workflow reduces friction and enhances daily efficiency.

Durability, Maintenance, and Lifecycle Value

A tray isn’t a disposable accessory — it’s a working tool. High-quality plastic trays are engineered for repeated handling, washing, stacking, and transport. Features like impact resistance, anti-slip textures, and reinforced edges extend service life.

Maintenance also matters. Trays designed with smooth corners and minimal seams are easier to sanitize, especially in food and clinical settings. Over time, these design choices contribute to lower operating costs and improved hygiene standards.

Choosing with Purpose

Ultimately, selecting the right tray is about aligning form with function. Whether organizing components, serving food, managing equipment, or supporting professional workflows, the tray should integrate seamlessly into its environment.

A thoughtful choice improves efficiency, protects materials, and enhances user experience — proving that even simple tools deserve careful consideration.

Contact Us

If you’re exploring tray solutions for storage, food handling, or specialized applications, professional guidance can make the selection process faster and more precise.

📧 Email: info@agghemp.com

🌐 Website: www.agghemp.com

💬 Consultation: Product customization & bulk inquiry welcome

Reach out anytime — the right tray solution starts with understanding how you work.

FAQs:

What is a plastic tray used for?

A plastic tray is designed for organizing, carrying, and staging items in both home and professional environments. Depending on the design, trays can support food handling, tool organization, retail display, or clinical workflows. Many buyers choose a plastic tray because it improves efficiency by keeping items stable and accessible.

Are plastic trays safe for food use?

A plastic tray for food is safe when made from food-grade materials that resist staining, odor absorption, and chemical breakdown. Smooth surfaces also make cleaning easier, which helps maintain hygiene. Always confirm that the tray is manufactured for food contact if it will be used in kitchens or catering environments.

How do I choose the right size plastic tray?

Start by identifying what the tray will carry and how often it will be used. A large plastic tray is ideal for transporting multiple items or heavier loads, while compact trays work better for drawer organization or countertop prep. Structural support and edge stability are just as important as size.

Can plastic trays handle heavy items?

Yes — many heavy-duty trays are reinforced to prevent bending or cracking under load. When selecting a tray for frequent lifting or commercial use, look for thicker bases and strengthened edges. This ensures durability and reduces long-term replacement costs.